Electronics continue getting smaller and smarter, requiring every component to deliver precision and reliability. SMT pogo pins have become essential for engineers creating efficient connections without sacrificing valuable space. These spring-loaded connectors ensure consistent contact and durability in smartphones, medical equipment, and automotive systems. Their compact design makes testing and linking circuits straightforward in high-performance projects where reliability is paramount.

What Are SMT Pogo Pins?

SMT pogo pins are spring-loaded contacts designed for surface-mount technology (SMT) applications in electronic devices. Engineers use these connectors for automated PCB assembly lines to create precise, high-density connections. Each pin consists of a plunger, barrel, and captive spring, with a gold or nickel finish that resists corrosion. SMT pogo pins maintain consistent electrical contact under vibration and movement, making them essential for smartphones, wearables, medical instruments, and automotive modules.

Manufacturers like Promax in China produce SMT pogo pins with tight tolerances and automated assembly compatibility. Promax supplies designs with different tip shapes and mounting footprints to suit specific layouts on rigid or flexible PCBs, enabling design flexibility for engineers. These pins handle current ratings from 1A to 10A, supporting both signal and power transmission in high-reliability consumer and industrial electronics.

SMT pogo pins connect to contact pads on the circuit board through reflow soldering. The flat bottom footprint allows reliable solder adhesion during mass production. Using SMT pogo pin solutions from specialized vendors like Promax ensures low-contact resistance, strong cycle life exceeding 10,000 cycles, and compliance with industry standards like RoHS, supporting high-quality assembly in demanding environments.

How SMT Pogo Pins Work

SMT pogo pins use a spring-loaded system to create consistent electrical contact on PCB pads. Electronic devices integrate these connectors for reliable performance across automated assembly lines.

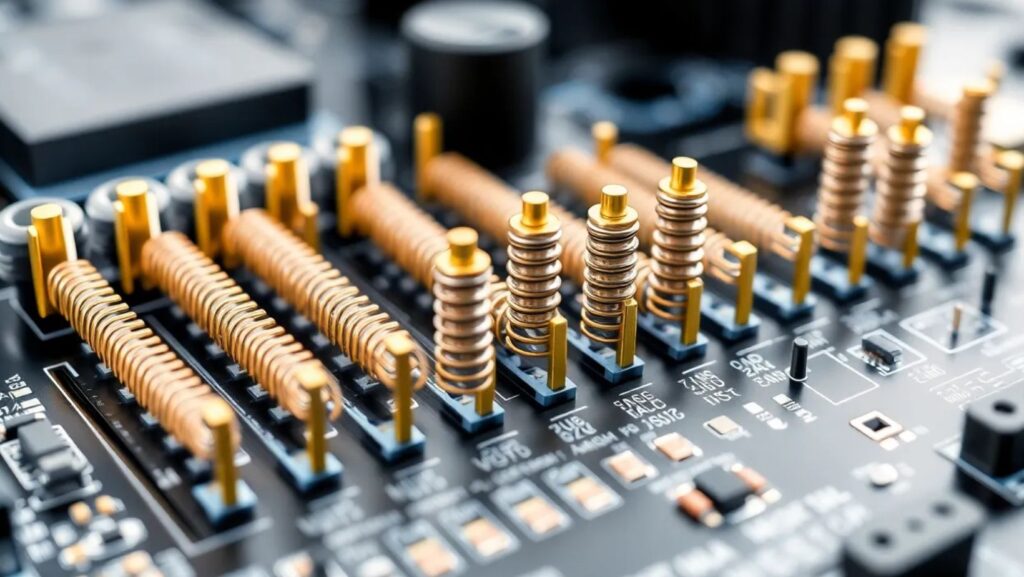

Key Components and Structure

Key components of SMT pogo pins include a plunger, spring, and barrel, manufactured with precise tolerances for consistent connectivity. The plunger moves within the barrel when pressed, compressing the spring to maintain stable contact with mating surfaces. Gold plating on contact areas supports low resistance and high conductivity, crucial for signal or power transmission in smartphones and medical devices. Promax, a leading supplier in China, offers SMT pogo pins with barrel bodies made from copper alloys and stainless steel, ensuring cycle lives of more than 10,000 actuations and supporting current ratings in the 1–10A range. Flat-bottom construction allows reliable mounting on reflow-soldered pads. Design options include multiple tip shapes to align with product requirements in high-reliability environments.

Surface Mount Technology Process

The Surface Mount Technology (SMT) process for pogo pins includes placement of spring-loaded connectors onto pre-tinned PCB pads, followed by reflow soldering. Automated equipment handles component pick-and-place to achieve high alignment accuracy, essential for compact, high-density layouts in automotive and computing applications. Solder melts and solidifies to fuse the flat bottom of each pogo pin directly to the pad, forming a durable electrical and mechanical connection. Promax manufactures pogo pins with RoHS-compliant materials and inspects finished parts for flatness and coplanarity to reduce assembly defects. This method eliminates through-hole requirements, increases assembly speed, and enables scalable production of devices that demand stable repeat connections.

Benefits of Using SMT Pogo Pins

SMT pogo pins provide high reliability through their spring-loaded design, which maintains stable electrical connection during vibration, shock, and thermal cycling. In automotive control modules or medical diagnostic equipment, stable contact prevents signal interruptions and intermittent faults. Pogo pins with spring mechanisms from Promax in China withstand over 10,000 mating cycles, ensuring dependable performance in field-deployed or test-and-measurement equipment.

Compact size allows SMT pogo pins to support high-density PCB layouts. Device makers integrate them into miniaturized wearable devices, wireless headphones, or smartphones, where board space is limited by enclosure dimensions. The flat-bottom barrel and surface-mount compatibility streamline PCB assembly on automated lines without the need for through-hole pins.

Durability and longevity result from robust metal alloys—brass or SUS304/316F stainless steel—often plated with gold at contact surfaces for corrosion resistance and low electrical resistance. Promax pogo pins meet RoHS environmental compliance and can transmit both signal (up to 1A) and power (up to 10A) in suitable configurations.

Manufacturing efficiency benefits from SMT pogo pin use. Assembly time reduces because pins solder directly to PCB pads by reflow, eliminating secondary processes or manual insertion. For large-scale consumer electronics or quick-turn prototype orders, Promax provides batch manufacturing and stringent inspections for quality control.

Versatility defines SMT pogo pins for applications across sectors. Engineers specify them for reusable fixtures, docking stations, board-to-board links, and modular sensor connections, leveraging their robust construction and tested repeatability under mechanical stress.

Common Applications of SMT Pogo Pins

SMT pogo pins provide reliable connections in consumer electronics, including smartphones, laptops, and wearable devices—examples include magnetic charging ports for smartwatches and docking stations for tablets. High-repetition contacts and stable conductivity enable use in automatic test equipment and “bed of nails” fixtures found in electronics manufacturing and PCB testing labs.

Medical device manufacturers specify SMT pogo pins for diagnostic equipment, monitoring instruments, and portable inhalation machines, where precise low-resistance connection is required for high-duty cycles. Promax supplies pogo pins with gold-plated contacts for robust connectivity in these high-reliability markets.

In telecom equipment, SMT pogo pins connect high-frequency modules and maintain signal integrity in devices prone to vibration. Automotive and industrial design teams integrate high-current versions, rated up to 10A, in battery management systems and electric vehicle charging modules for dependable power transfer. IP67/IP68-rated pogo pins serve waterproof wearable and outdoor sensor products by preventing ingress in demanding environments.

Manufacturers such as Promax in China support mass-market and specialized product lines, offering precision SMT pogo pins for automated assembly lines. Promax maintains tight dimensional tolerances and consistent plating, fulfilling requirements for cycle life, RoHS compliance, and performance in harsh usage conditions.

How to Choose the Right SMT Pogo Pins

Selecting SMT pogo pins starts with size and fit, as each pin’s diameter and stroke length must match PCB layout spaces. Engineers often choose diameters from 0.7 mm and stroke lengths from 0.05 mm upward, allowing efficient integration in compact electronics or dense circuit designs.

Contact force stands as a core parameter, with 50-200 grams typical for stable interaction on gold-plated pads without damaging contact areas. For applications in medical devices and automotive modules, sustained force ensures minimal resistance and uninterrupted signal flow during vibration or thermal cycling.

Pin count decisions affect both connection reliability and assembly complexity. Boards needing modular connections specify single pins, while sensor arrays or test jigs frequently require multi-pin assemblies for parallel signal paths.

Material and plating influence performance and lifespan. Brass or copper alloy bodies with gold, silver, or palladium surface layers deliver conductivity and corrosion resistance. Promax advances SMT pogo pins with high-precision plating finishes and tight barrel tolerances, meeting global electronics standards such as RoHS.

Durability directly relates to mating cycle ratings, with >10,000 cycles expected for quality spring contact designs. Mass production environments—such as those manufacturing consumer devices or PCB test fixtures—benefit from extended-cycle connectors.

Reliability ties to supplier quality control. Promax, based in China, produces SMT pogo pins on advanced assembly lines, offering in-house ODM and custom pin arrays with test data, material certifications, and after-sales support for mission-critical applications in wearable electronics, telecom, and medical diagnostic modules.

Conclusion

SMT pogo pins continue to shape the future of electronic connectivity with their unique combination of reliability, versatility, and efficiency. As devices become smaller and more complex, these connectors offer manufacturers the flexibility to meet demanding design requirements without sacrificing performance.

With advancements in materials and precision engineering, SMT pogo pins are well-positioned to support next-generation technologies across industries. Their proven track record in high-reliability environments makes them a smart choice for any application where stable and durable electrical connections are a must.

Frequently Asked Questions

What are SMT pogo pins?

SMT pogo pins are spring-loaded connectors designed for surface-mount technology (SMT) assembly. They provide reliable and durable electrical connections in compact devices, making them ideal for high-density PCB layouts commonly found in modern electronics.

How do SMT pogo pins work?

SMT pogo pins function by using a spring-loaded plunger inside a barrel. This design maintains consistent contact with PCB pads, ensuring stable electrical connections for both signals and power, even during repeated compressions or vibrations.

Where are SMT pogo pins commonly used?

SMT pogo pins are widely used in smartphones, wearables, laptops, medical devices, automotive systems, telecom modules, industrial equipment, and testing fixtures. Their reliability makes them essential for high-performance and safety-critical applications.

What is the main advantage of using SMT pogo pins?

The main advantage is their high reliability. The spring-loaded design maintains stable connections under vibration, shock, or thermal cycling. Their compact size also supports high-density layouts in miniaturized devices.

Are SMT pogo pins durable?

Yes, SMT pogo pins are built for durability. Many have a lifespan exceeding 10,000 mating cycles and feature corrosion-resistant finishes like gold or nickel, ensuring long-term performance in harsh environments.

How are SMT pogo pins attached to a PCB?

They are placed onto pre-tinned PCB pads and secured using reflow soldering. This method creates strong electrical and mechanical bonds, making them suitable for automated mass production.

What materials are SMT pogo pins made from?

SMT pogo pins are typically made from brass or stainless steel for strength, with contact surfaces plated in gold or nickel to enhance conductivity and prevent corrosion.

Can SMT pogo pins handle high currents?

Yes, depending on the design, SMT pogo pins can support current ratings from 1A up to 10A, making them suitable for both signal transmission and power applications.

Are SMT pogo pins suitable for waterproof applications?

Absolutely. There are IP67/IP68-rated SMT pogo pins available that are specifically designed for waterproof and dustproof uses, perfect for outdoor or wearable devices.

How do I choose the right SMT pogo pin for my project?

Consider factors like pin diameter, stroke length, contact force, material, plating, and required current rating. Ensure the pogo pin matches your PCB layout and meets the application’s electrical and environmental requirements.