Factories and packaging lines rely on precise inspection to maintain quality and safety standards that protect brands and consumers. Human inspectors catch obvious defects but miss subtle issues when fatigue sets in or production speeds exceed what eyes can reliably monitor without errors slipping through.

Modern vision systems use advanced cameras, lighting, and AI-driven analysis to catch defects faster and more accurately than human eyes. These systems never tire, maintain consistent standards across shifts, and detect problems humans simply cannot see at production speeds where milliseconds determine whether defects reach customers or get caught in time.

How vision systems are revolutionizing quality control across manufacturing industries changes everything about inspection capabilities and costs. Understanding real-time detection, AI improvements, waste reduction, and integration ease helps manufacturers decide when upgrading inspection technology makes sense for their specific operations and quality requirements.

Real-Time Defect Detection at High Speeds

Camera systems capture images of products moving at speeds where human inspection becomes impossible without slowing production. High-speed cameras combined with specialized lighting freeze motion and reveal defects in microseconds, processing thousands of items per minute that would require dozens of human inspectors working simultaneously. Speed advantages alone justify vision systems for high-volume operations.

Immediate feedback allows automated rejection of defective items before they continue downstream or reach packaging. Real-time detection means bad products get diverted instantly rather than contaminating batches or requiring manual sorting later. This instant response prevents defects from accumulating and reduces waste from entire production runs ruined by undetected upstream problems.

Multiple inspection points throughout production lines catch issues at various stages rather than waiting until final inspection. Vision systems positioned strategically identify problems immediately after they occur, allowing operators to correct processes before producing more defective items. Early detection minimizes waste and downtime compared to discovering problems only after producing thousands of bad units.

AI and Machine Learning Improving Accuracy

Pattern recognition algorithms learn what acceptable products look like and identify deviations automatically without programming every possible defect scenario. AI-trained systems adapt to product variations and detect anomalies that rigid rule-based inspection misses. This flexibility handles complex quality requirements that would take months to program using traditional machine vision approaches.

Continuous learning improves detection accuracy over time as systems analyze more products and receive feedback about missed defects or false positives. Unlike human inspectors whose performance degrades with fatigue, AI systems get better with experience, constantly refining decision-making based on accumulated data. This improvement curve means vision systems become more valuable the longer they operate.

False positive reduction saves money by preventing good products from being rejected incorrectly due to overly sensitive inspection criteria. AI systems balance sensitivity with specificity better than simple threshold-based detection, distinguishing between cosmetic variations and actual defects that affect function or safety. Smarter rejection decisions improve yields while maintaining quality standards.

Reducing Waste and Rework Through Early Detection

Catching defects early prevents value-added processing of items that will eventually be scrapped or reworked. Identifying bad parts before assembly, coating, or packaging saves labor and materials that would be wasted completing products destined for rejection. Early intervention economics improve dramatically when expensive downstream processes can be avoided entirely.

Root cause analysis becomes easier when vision systems track defect patterns and correlate them with process variables. Data showing when and where defects occur helps engineers identify equipment issues, material problems, or process drift causing quality failures. This diagnostic capability prevents recurring defects that manual inspection documents but doesn’t explain clearly enough to enable fixes.

Scrap reduction directly improves profitability by lowering material waste and rework labor that consume resources without producing saleable products. Even modest improvements in first-pass yield translate to significant cost savings for high-volume operations where percentage point gains multiply across millions of units annually. Vision systems pay for themselves through waste reduction alone in many applications.

Seamless Integration Into Existing Production Lines

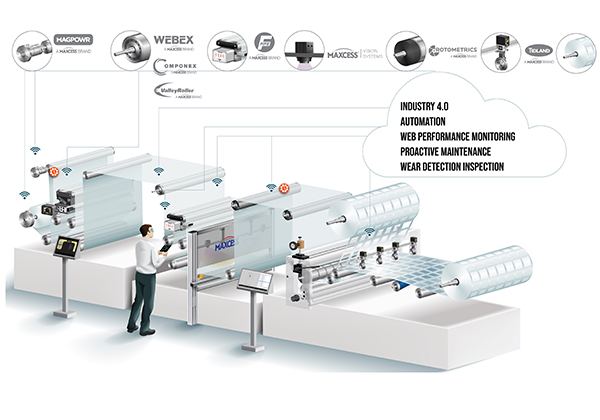

Retrofit installations add vision inspection to existing lines without major production disruptions or equipment replacements. Modern systems mount easily, communicate with existing controls via standard protocols, and operate alongside other equipment. This compatibility lets manufacturers upgrade quality control incrementally rather than requiring complete line rebuilds that halt production for extended periods.

Communication standards allow vision systems to share data with factory networks, quality management systems, and production tracking software. Integration provides traceability linking inspection results to specific products, batches, and production conditions. This connectivity supports compliance requirements and continuous improvement initiatives that depend on detailed quality data.

Scalability lets manufacturers start with single inspection points and expand as ROI proves itself and budgets allow additional investment. Modular approaches reduce upfront costs while establishing infrastructure supporting future expansion. Starting small demonstrates value and builds internal expertise before committing to facility-wide vision system deployments that require larger investments.

Conclusion

Vision systems boost quality and efficiency by catching defects humans miss while operating at speeds manual inspection cannot match. AI improvements, waste reduction, and integration flexibility make modern vision technology accessible and practical for manufacturers of all sizes seeking competitive advantages through superior quality control.

Manufacturers should explore upgrades for competitive advantage rather than viewing vision systems as expensive luxuries only industry leaders can afford. Technology costs have dropped while capabilities have increased, making vision inspection economically viable for operations that previously relied entirely on manual methods. Improved quality and reduced waste often justify investments within months rather than years.